IMTEX 2026: Our Technology for the Indian Market

IMTEX will host Crippa and SMI solutions for tube processing. Visit us to explore technologies that enhance production efficiency and process precision.

Explore our range of products for HVACR, Data Centers, and tube processing.

A comprehensive service ecosystem designed to ensure maximum performance for your work.

Service is the beating heart of every successful business: it’s not just about keeping products running but transforming them into tools that enhance productivity, optimize costs, and improve sustainability. With tailored solutions, global support, and a focus on efficiency, we ensure that every machine becomes a growth engine for our customers.

Service is not a cost—it’s an investment in the future of your business.

Service Remote Support

To ensure fast and effective support, we offer:

an advanced ticketing system

integration of the ticketing system with our ERP/Lyra

Phone support and remote assistance from our specialized technicians

on-site interventions performed by our field engineers

Additionally, we provide dedicated QR codes for immediate access to technical resources and support procedures.

Maintenance

We offer tailored maintenance solutions to prevent failures and improve the performance of your machines. Thanks to the TCO Cube device, we continuously monitor the status of the equipment, enabling timely interventions and ongoing optimization of their lifecycle.

Choosing our service means relying on highly qualified technical support and advanced technologies to ensure maximum efficiency and productivity for your plants.

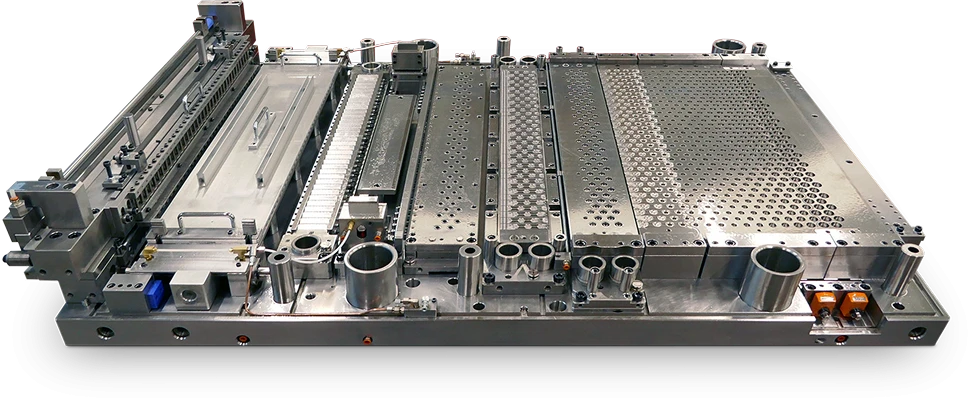

Fin-Dies

We manufacture progressive dies for fin packs, designed to ensure maximum production efficiency.

Additionally, we offer a comprehensive support and maintenance service, including the supply of new dies, refurbishment of existing ones, and replacement of individual components when necessary.

This ensures that your production always maintains the highest levels of efficiency and reliability.

Spareparts

We guarantee the highest quality and speed in the supply of original spare parts for your machines, thanks to an efficient logistics organization and certified production standards.

Our logistics centers are strategically distributed worldwide, ensuring comprehensive coverage and optimized delivery times.

Thanks to an advanced management system, we can quickly provide the necessary spare parts, minimizing machine downtime and ensuring production continuity.

All our spare parts are manufactured using cutting-edge production methods and undergo rigorous quality checks. Choosing our original components means opting for reliability, high performance, and long-lasting durability for your machinery.

Trust OCTA Group for a fast, safe and certified spare parts supply service.

Tooling

We manufacture tube bending and end-forming tooling, designed to ensure maximum production efficiency and high precision in processing. Our solutions are developed to deliver optimal performance and long-term reliability.

That's why we stand by your side in the development of equipment for new production processes, offering a comprehensive support and maintenance service. This includes the supply of new tube bending and forming toolsets, as well as replacement of individual components when needed.

This way, we ensure that your production consistently maintains the highest standards of efficiency and operational continuity.

Software Updates

Our software solutions are designed to optimize production processes, maximize plant efficiency, reduce errors, and protect your production.

With a dynamic and interactive system, our software updates ensure that your machines always operate at peak performance.

To drive continuous innovation, our in-house development team works every day to enhance our software, addressing new market challenges and delivering cutting-edge, high-performance solutions.

Line Relocation

We offer a global production line relocation service, managed by our engineers and logistics specialists.

Complete transfer management to minimize risks

Minimized machine and plant downtime

Optimized installation for a fast and secure restart

With OCTA Group, you have the guarantee of a reliable partner, capable of optimizing every phase of your project, from planning to implementation, with tailor-made solutions to meet your production needs.

Retrofitting

Our retrofitting processes allow you to:

Optimize return on investment, extending the lifespan of your machines

Reduce the need for frequent replacements, lowering operating costs

Integrate the latest technological innovations, enhancing performance and efficiency

Implement automation and handling systems, increasing productivity and safety

With our retrofitting service, your machines will always be up-to-date, reliable, and ready to meet market challenges.

Training

Our customers can choose from various training modules, creating a customized learning path tailored to their specific needs.

We offer personalized training courses, available both at our facilities and on-site. With the support of our specialized trainers, we provide hands-on assistance and targeted training programs, ensuring maximum operational efficiency in the use of your equipment.

Tell us about your goals

A team driven by passion, dedicated to designing and developing innovative, efficient, and sustainable technologies for tube processing, HVACR systems, and Data Centers—working in constant synergy with its clients. Our expertise is at your service to provide specific, cross-sector, and highly customized solutions, ensuring consultancy, training, and support at every stage of the production process.

Upload your project in the box to request your feasibility analysis.

Tailor-Made Solutions for Every Production Need

Every production environment has its own unique characteristics, specific challenges, and complex requirements that demand customized solutions. At OCTA Group, we understand this well, which is why we provide highly personalized solutions, designed to seamlessly integrate into your processes and enhance the performance of your machines.

Our strength lies in our ability to deeply understand your needs, analyze critical issues, and develop advanced technologies that precisely meet even the most complex production demands. We don’t just provide machines or services—we build fully integrated, tailor-made solutions aimed at maximizing efficiency, quality, and productivity in your operations.

Finding the right solutions to our customers’ challenges is in our DNA. With our experience and continuous investment in innovation, we design and implement custom systems, combining automation, precision, and reliability. Every project is a challenge we take on with passion, leveraging our expertise to create solutions that deliver concrete and lasting results.

Choosing OCTA Group means partnering with a team that can transform your needs into cutting-edge technological solutions, tailored to your production. If you have a complex challenge, we are ready to find the perfect solution for you.

We combine various technologies and processes to boost your efficiency

Integrated work cells provide advanced solutions for efficiently producing complex and innovative products with high yield. By combining different technologies and processes, these systems enhance efficiency, productivity, and flexibility, optimizing cycle times and reducing waste.

All of this is managed by a single supplier with multidisciplinary expertise, capable of delivering turnkey solutions tailored to your needs.

Turnkey solutions for high-volume production

When it comes to high-volume production, reliability, speed, and efficiency are essential to maximizing output. At OCTA Group, we design and manufacture customized transfer systems, developed to optimize production cycles, reduce processing times, and ensure consistent results, even in the most demanding applications.

Every production plant has its own unique needs, and our goal is to provide perfectly integrated solutions that align with your processes. Through a detailed analysis of your production requirements, we develop innovative transfer systems, capable of handling high volumes with exceptional repeatability, absolute precision, and minimal waste.

Customization is our strength. Each transfer system is designed with advanced technologies, intelligent automation systems, and high-quality materials, ensuring high performance, long-term reliability, and reduced maintenance needs. Additionally, our solutions are engineered to enhance ergonomics and operator safety, further improving overall efficiency.

Choosing OCTA Group means relying on a partner capable of delivering tailor-made transfer systems, designed to support high production rates without compromising quality and precision. If you need a high-performance system for your plant, we are ready to provide the perfect solution.

Flexibility throughout the entire production process

We develop customized solutions, integrating existing and new technologies to meet specific needs.

Our integrated work solutions include vision systems, inline control, and monitoring solutions that enhance quality while reducing waste, increasing efficiency, and optimizing workflows, all while ensuring maximum flexibility throughout the entire production process.

Additionally, they offer real-time traceability, allowing you to make quick, data-driven decisions, optimize production volumes, and achieve quality goals.

Streamline production processed through robot technology

Our expertise in industrial automation and system integration enables us to develop advanced solutions that make extensive use of robots and robotic systems, designed to streamline production processes and ensure maximum performance.

The use of robotic technology brings numerous advantages, including:

Increased productivity – Faster execution speeds and reduced cycle times

Absolute precision and repeatability – Eliminates human error and ensures consistent quality

Operational flexibility – Easily adapts to various production requirements

Cost reduction – Lower labor needs and minimized waste

Enhanced safety – Reduces workers' exposure to repetitive or hazardous tasks

With our expertise in industrial robotics integration of various kind and brand, we design systems that seamlessly interact with existing technologies, ensuring a smooth, efficient, and cutting-edge production process.

Choosing OCTA Group means partnering with a leader in automation, delivering intelligent, reliable, and customized solutions to meet your specific production needs.

Software

The evolution of design starts with shapes: elegant tubular structures, flawless curves, and uncompromising creative freedom. With the new R42E, precision and aesthetics come together to create unique furniture solutions.

Explore new possibilities.

Made with high-quality materials, the molds are designed to ensure impeccable

precision in creating the required geometries.

We can help you design your workshop and select the most suitable machines for your needs from our range of solutions. With our expertise, we help you integrate the machines, optimize the production processes and ensure the highest level of efficiency. We also work with you to develop the most functional layout, minimizing space and energy consumption to provide you with a sustainable, high-performance configuration.

We develop customized solutions by integrating existing and new technologies to meet specific needs. Our integrated work solutions enhance quality by reducing waste, increasing efficiency, and optimizing workflows while ensuring maximum flexibility throughout the production process. Additionally, they provide real-time traceability, enabling you to make quick decisions based on actual data to optimize production volumes and quality objectives

OCTA Group is more than a supplier—it’s a partner that supports you in every stage of your work. From selecting the right solutions to optimizing processes, we provide continuous assistance and tailored consulting. Our goal is to deliver high-performance machinery and a service that makes every project more efficient. With our expertise, we optimize time, costs, and results, ensuring constant technical and strategic support to help you achieve your goals.

Our technological solutions comply with Industry 4.0 and 5.0 requirements, ensuring innovation, efficiency, and sustainability. With our expertise and strong partnerships, we support you in selecting the most suitable solutions for your needs and guide you through the process of obtaining the tax benefits provided by these regulations, maximizing the value of your investment. With OCTA Group, you have a reliable partner for a smarter and more competitive industry.

We offer a comprehensive support in choosing the leasing solutions that best suit your needs, thanks to its strong partnerships. Whether you are looking for payment flexibility, advantageous terms or a plan tailored to your business, we will help you choose the best option, ensuring efficient and customized solutions to optimize your investments. Want to learn more?

We can help you design your workshop and select the most suitable machines for your needs from our range of solutions. With our expertise, we help you integrate the machines, optimize the production processes and ensure the highest level of efficiency. We also work with you to develop the most functional layout, minimizing space and energy consumption to provide you with a sustainable, high-performance configuration.

We develop customized solutions by integrating existing and new technologies to meet specific needs. Our integrated work solutions enhance quality by reducing waste, increasing efficiency, and optimizing workflows while ensuring maximum flexibility throughout the production process. Additionally, they provide real-time traceability, enabling you to make quick decisions based on actual data to optimize production volumes and quality objectives

OCTA Group is more than a supplier—it’s a partner that supports you in every stage of your work. From selecting the right solutions to optimizing processes, we provide continuous assistance and tailored consulting. Our goal is to deliver high-performance machinery and a service that makes every project more efficient. With our expertise, we optimize time, costs, and results, ensuring constant technical and strategic support to help you achieve your goals.

Our technological solutions comply with Industry 4.0 and 5.0 requirements, ensuring innovation, efficiency, and sustainability. With our expertise and strong partnerships, we support you in selecting the most suitable solutions for your needs and guide you through the process of obtaining the tax benefits provided by these regulations, maximizing the value of your investment. With OCTA Group, you have a reliable partner for a smarter and more competitive industry.

We offer a comprehensive support in choosing the leasing solutions that best suit your needs, thanks to its strong partnerships. Whether you are looking for payment flexibility, advantageous terms or a plan tailored to your business, we will help you choose the best option, ensuring efficient and customized solutions to optimize your investments. Want to learn more?

A global partner to assist you worldwide

Wherever you are, from the most populated areas to the most remote factories, OCTA is ready to support you—remotely or on-site—through a team of highly skilled professionals and technicians.

+30.000m2

production plants

+80

countries with OCTA machinery

+10.000

installations

OCTA Social awareness

OCTA Hub

IMTEX will host Crippa and SMI solutions for tube processing. Visit us to explore technologies that enhance production efficiency and process precision.

It was a pleasure meeting so many of you, sharing ideas, and discussing the future of tube bending and automation.

We look forward to building on the connections made at the event and continuing to drive innovation together.

A unique opportunity to explore up close highly automated industrial solutions designed to optimize productivity, quality, and flexibility in production lines. Our technical and sales team will guide you in selecting the solutions that best suit your production and application needs.